Additive Manufacturing

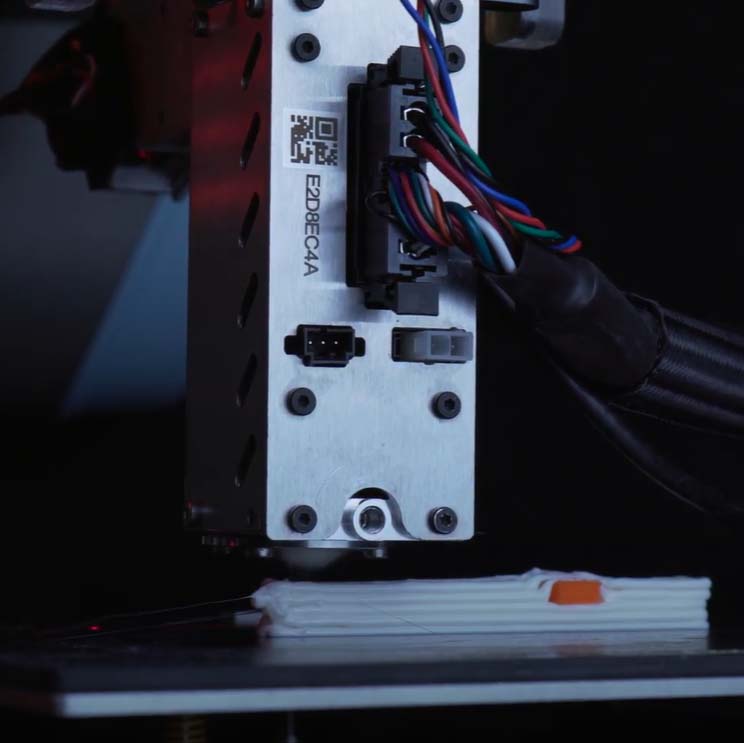

Increased usage of additive manufacturing (AM) in various industries has solidified its role as an advanced manufacturing technique. However, there is an inherent lack of reliability in AM processes, particularly common in extrusion or deposition-based methods due to the stochastic nature of material deposition. This necessitates an intelligent manufacturing solution to address the drawbacks of AM. Thus, we propose a novel layer-wise approach toward closed-loop AM, which is capable of in-situ monitoring and repairing geometric defects. We developed a system that uses a robotic AM experimental platform that mimics a conventional open-loop fabrication setup, which we augment into a closed-loop system using two add-ons: in-situ inspection subsystem and online process correction subsystem. The in-situ inspection subsystem collects 3D point cloud scans and compares them against a reference CAD model, categorizing geometric deviations as positive or negative defects. Then the subsequent online process correction subsystem uses a re-plan and/or repair strategy to address the positive and/or negative defects, respectively. To evaluate this idea, we conducted three experiments on parts with manually induced defects to investigate the system’s ability to repair those parts, thereby reducing defects, improving part accuracy, and enhancing mechanical properties. Comparing the defective and repaired parts, we observe a reduction in defect percent by volume from 10.7% to 1.3%, an improvement in geometric tolerance from 3.86% error to 0.08% error, and an increase in the part’s breaking load from 4.77 kN to 6.31 kN. These experiments prove that our layer-wise closed loop additive manufacturing approach improves the quality, tolerance, and reliability of plastic 3D printed parts, with the potential to extend to other extrusion/deposition-based AM processes, or even subtractive manufacturing and hybrid manufacturing methods